Kasama Ware

Pottery originated in Kasama-shi, Ibaraki Prefecture, design without being caught by tradition

Kasama is located in the western part of Ibaraki Prefecture, mainly a basin surrounded by the mountains. Kasama Inari Shrine was built in the Nara period, and it is known as the three major Japanese shrines. It is famous as the guardian deity of all promotion of industry. As time passes, the town grew as a temple town, castle town, and post town. Now the town is known for its tourism industry, the stone industry of granite, and agriculture focusing on rice. On the other hand, Kasama is famous for its ceramics which is known as Kasama Ware which has become a precious traditional culture.

Kasama Ware began in the Anei period (1772-1781) when Kuno Hanemon from Hakoda town built a climbing kiln with Choemon, who was a Shigaraki's potter. Afterwards, Haemon's son-in-law succeeded the Kuno Kiln and produced tableware. Pottery industry was taken up as one of the new income source instead of agriculture which was damaged by the natural disaster or bad harvest in the Kasama's land. Kasama Ware which was made in Edo period were usually used in daily life and its style was influenced by Shigaraki, such as the jars, the earthenware mortar, and the candle stand, the candle dish, Binbo-tokkuri (the sake bottle), the hot water bottle, the oil container, Benibachi (the tea ceremony brazier), the bowl with one spout, Surioroshizara (the small plate), Hibachi (the small Japanese charcoal heating appliance), Haifuki (the cylindrical bamboo ash tray), Nizomesara (the rectangular plate). In the Meiji Era, country owned kilns turned into private kilns, and the market also spread to all over Japan.

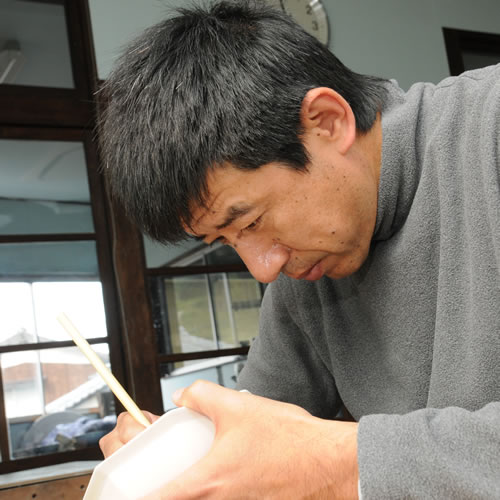

The characteristics of Kasama, is that it produces various types of clay. Above all, Kisetsu clay or Gairome clay, which its main ingredients are granite's fragment was highly used. They are rich in plasticity and contain much iron, so it turns brown after it is fired. Potter usually glazes after biscuit to reduce water absorbency since these clays tend to absorb water. Generally the process begins in mining clay → kneading clay → molding → decoration → drying → biscuit → glazing → firing. Potter's wheel is often used in molding, as well as Kataokoshi (plaster) or Tebineri (forming by hand) are also used.

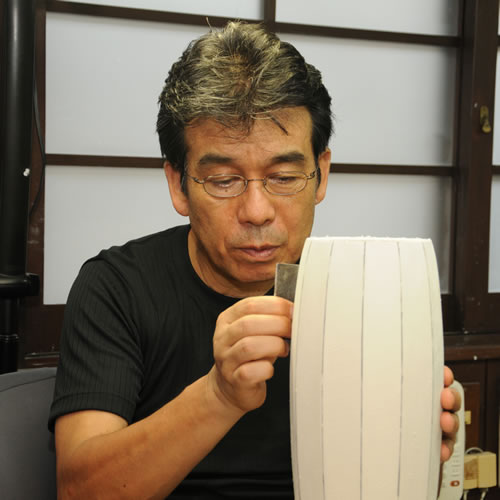

The techniques used when using the potter's wheel are "Kirizukuri", "Tamazukuri", "Kirikaeshi", "Tsugimono". Especially a large-sized ceramic is ground by two persons using the Tsugimono technique. To decorate the ground after molding, the "Dorogake (pouring the mud made by white clay)" technique is used. Since the Kasama's clay contains iron, in order to cover the ceramic in reddish brown color, in Meiji 20s (1887-1897), mortar were poured to the bottom of the jar or the earthenware. In addition to the white clay, sometimes the yellow brown colored clay were used, and "Dobuzuke" or "Hishakugake (soaking directly in the mud)" was done. And there are Hakeme (with brush mark), Hori (curving), Tobikanna (curving roughness pattern), Icchin (slipware), Monyozuke (pasting patterns) used for the other decorations.

After drying and biscuit, painting colors under the glaze and glazing are done as decoration before firing. Glazing techniques used here are Hitashigake (dripping), Nagashigake (flowing), Hakegake (glazing by brush), Tsutsugake, Kushimegake (scratched by the comb), Kakkiotoshi (sgraffito), etc. Techniques used for painting colors under the glaze are "Sengakimoyo (drawing pictures by using the lines)", "Bokashi (gradation)", "Icchin (slipware)", where painting by the brush is done. In Kasama's pottery industry, in order to produce mass tableware, it can also be said that the decoration by glazing such as "Nagashigake" took the lead more than decent painting, since the ground made by the clay which contains much iron turns into the brown color after firing. Multi-chambered climbing kiln was built by using the slope landscape of Kasama surrounded by the mountains. However, its slope was not stepped type, but landslide type which was covered with the sand granules thickly, so it was called "Sunagama (sand kiln)".

In this way, Kasama Ware was born in the middle of the Edo period, and the style of Kasama Ware was established after Meiji period. After World War Ⅱ, it was well-known as the folk tableware. There is the history which was developed being subject to the influence from the other pottery and especially in Meiji period, ITAYA, Hazan from Shimodate who led Japanese modern ceramic art mastered the decoration by painting. Characteristics of Kasama which does not restrict its decoration, gives ceramic artists a possibility of a new ceramic design. MATSUI, Kosei who was the maestro of Neriage (kneading different clays) technique gave us the contemporary original arts based on the traditional technique, and he was awarded the Important Intangible Cultural Asset. There are a lot of ceramic artists who try various designs, and create many avant-garde modern ceramic arts beyond the traditional art craft.